Additive manufacturing in the job shop: Use cases

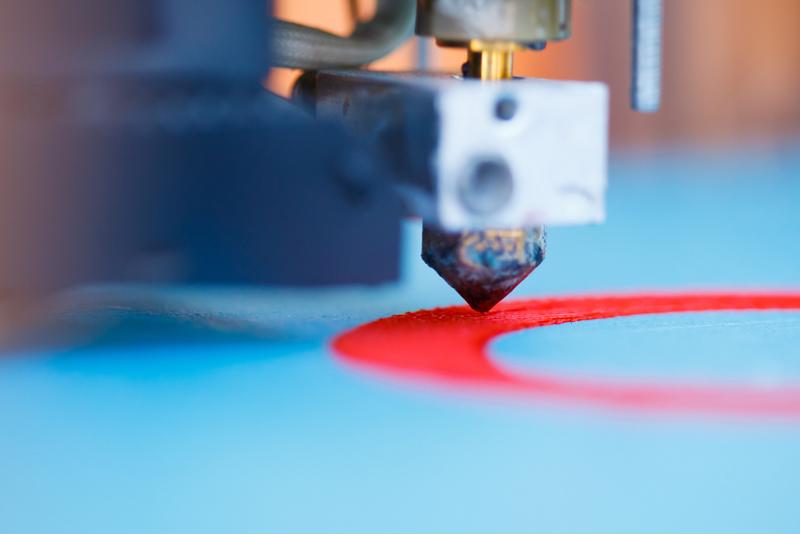

In recent years, 3D printing has become much more popular, both as a desktop tool for home users and for practical applications on the shop floor.

In the manufacturing world, 3D printing is sometimes known as additive manufacturing.

The growing consensus is that additive manufacturing will have a central role in many manufacturing processes in the future. In fact, a study commissioned by Essentium found that 58% of respondents believed 3D printing would be used for full-scale production of parts in the future, as reported in Industry Week.

How should forward-thinking machine shops approach this technology?

Prototyping: Getting started

For a job shop that wants to use 3D printing, there are many factors to consider, including price points and in-house expertise.

There are currently several lower-level and middle-tier 3D printers that are adequately suited to prototyping and small-run production needs.

Purchasing one of these models can be a good way for smaller job shops to get acquainted with the technology and start conceptualizing how they could leverage it efficiently for future jobs. For a preliminary trial run, renting the equipment may be a good idea, too.

If you have a reliable stream of jobs coming down the pike that would be a good fit for leveraging a 3D printer, investing in a production-grade metal additive manufacturing machine could be helpful.

The next level: Benefits of metal additive manufacturing

Beyond prototyping and small-run production, the recent development of innovative techniques in metal additive manufacturing has meant that this technology is now suitable for integration into existing manufacturing processes, perhaps even for job shops.

Using a process known as binder jetting, coupled with an additional sintering process, these powerful new 3D printers are finally able to compete with casting for speed and cost-effectiveness, though sintering does necessitate the use of a furnace, and machining may be required to smooth parts as well.

That said, 3D printing, particularly metal printing, is advancing at a very quick rate. Overinvesting in the technology without a sound plan for you using it effectively on your pending jobs could put you behind. As with most things, it's probably best to start slow. Investing in a less expensive prototyping machine is a good way to start thinking about how you'll use the technology in the future.

Implementing an enterprise resource planning (ERP) solution in the job shop can help you gain greater insight into your production processes and costs. Learn how today.